ADVERTISEMENT

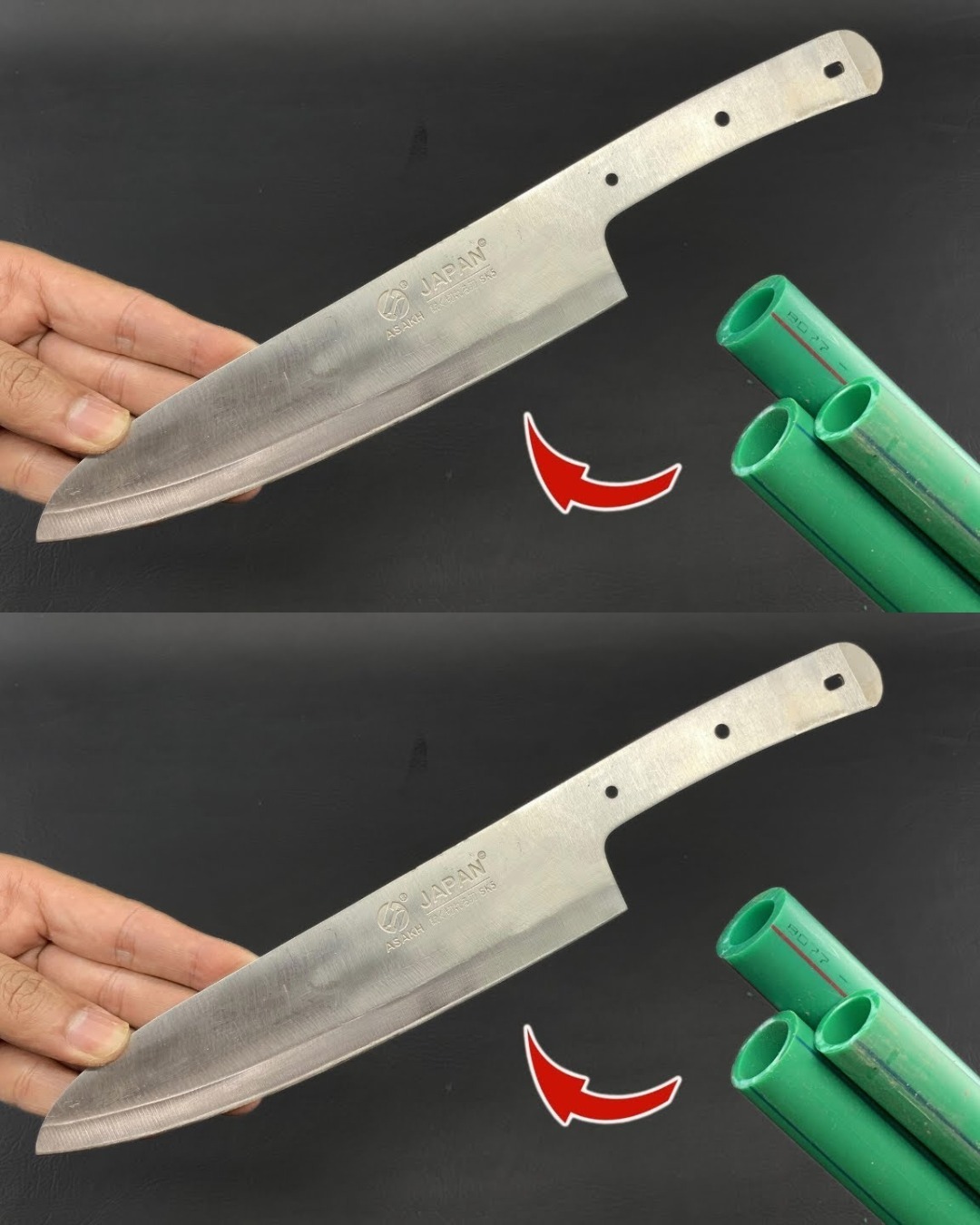

In the world of cutlery, the durability and grip of a handle are essential for functionality and comfort. While traditional materials like wood, micarta, or G10 are commonly used for knife handles, they can be expensive and require advanced skills to work with. However, there’s an affordable and accessible alternative: PVC pipe. This material offers an inexpensive way to create highly durable and custom knife handles.

This article reveals a little-known trick to making knife handles from PVC pipe—a method that is simple, cost-effective, and gives common materials a new life.

You can also watch the procedure in this video from the Creation Holic channel:

Why Use PVC for Knife Handles?

PVC is incredibly versatile, and its use for making knife handles offers several advantages:

- Cost-Effective: PVC is inexpensive and widely available.

- Durable: It can create long-lasting, sturdy handles.

- Customizable: You can shape it to fit various designs and sizes.

- Eco-Friendly: Reusing old PVC pipes helps reduce waste and gives them a second life.

Materials You’ll Need:

- PVC pipe (size depends on desired handle dimensions)

- A knife without a handle

- Heat source (such as a heat gun)

- Water for cooling the PVC

- Cutting tools (saw or utility blade)

- Sandpaper or sander

Step-by-Step Instructions to Create a PVC Knife Handle

see continuation on next page

ADVERTISEMENT